This looks like the same type of cover Johnny Chop used on his True Blue bike. The starting bid for this item was $450.00 where I found it. I think I can do a little better than that. If there is something being made by someone today, I wont be doing a re-pop of it. Just wont go there! However if it's not being manufactured today, I'll consider it fare game. I think this particular cover is being made in Europe? I'll have to check on that though. I have enough of my own ideas that I will never get em all cast in my lifetime as it is. Why waste time even trying to rip off someones hard work and sweat? I sure as hell wouldn't like it if it were done to me!

Hell, even if I don't get to cast everything I want to there will at least be a pic of every vintage part I wanted to do on here!

Monday, February 28, 2011

Welcome to Blue Collar Motos Metal Foundry!

OK! Got things changed over to the new address! Not everything is as clean as it was. I'm using Windows Vista now, and it didn't cooperate with me in changing over the info. The posts are broken up a bit but still easy enough to figure out, I hope. I have a bunch of stuff to post, but all the pix are still in the old computer. I'll be changing things over little by little, and going back to posting something once a day.

Title change on the way.

Stuff is stuff, but stuff with fins is cool! I got these pix from Shovelhead Steve over on the Horse Board. Haven't had time to go looking for any pix of other stuff I want to do yet. I'll keep posting pix as I come by them.

This first cover is super sweet! Would be a bit high in price due to the machine work involved, although I'm sure it would be less than a like new old cover from the 70s.

A set of fat-bobs went into making this tear drop.

I used a wire and a paint marker to scribe the parting line where I will cut the tanks in half. I cant cut them here though without getting my ass evicted. The landlord has no sense of humor when it comes to grinders and sawzalls. I'm thinking I could make a rubber mold and take the patterns out of them in plaster till I move to the new shop. It would be nice to have at least some things ready to go before the move!

Gate and Vent Options

My first idea on how to run the gates and venting system was to just use large enough vent risers to help fill the part with liquid metal during the solidification process. The thicker parts (mounting points) need to have metal flowing into them up till the time they turn solid. If not the shrinkage would most likely cause distortions in these thicker areas of the part as they cool and shrink. I also was thinking about running the Sprue down the center of the mold and sending the runners and gates to each of the mounting points. I'm sure the pattern would fill up just fine that way but, since the walls of the tank have such a large and relatively thin area throughout the mold, I decided to go with a bottom fed gating system. By feeding the largest section (front of tank) from underneath, its my hope to have very little turbulence in the metal as it flows threw the mold. I'm probably over thinking this but I know turbulence is bad, and it will probably be easier to gate the mold this way anyhow.

So then I started reading about directional solidification. What that is, is where the metal first starts to go from a liquid to a solid and continues to solidify from that point on threw the part. By adding chunks of metal to the mold you can decide where the solidification process begins. In my gas tank mold I would want to add the chill plates to the tank mounting points. The advantages in doing this are, the way the metal sets up with a chill plate makes for a more mechanicaly strong area. It has to do with the way the metal molicules lighn up during solidification. Thats another topic for another post though. Also, by chilling the larger parts (not close to the gate. Wouldnt want to stop metal flow threw the supply gates.) first, there is less of a chance that they will deform from a lack of liquid metal in their center during silidification due to shrinkage. Another plus for using chill plates, and one of the biggest is in the amount of metal needed to fill the mold. If I were to just put big ol risers on top of the mounting points, I could probably kiss a pound of aluminum good by for each mold I fill during a melt. That would have me melting enough extra aluminum to make the large riser concept not such a good idea. More melting time, more metal, more slag, etc, to deal with over all. If I were only planning on casting one part per melt then it wouldnt matter much. However I plan on spending a good five hours pouring as many molds I can make each time I fire up the furnace.

I would use more vents with the chill plates, but they get poked in with a coat hanger size wire, so its not a big deal. I'm also planning on using Petrobonded sand. The pertobond uses oil rather than water to hydrate and does not create steam. Since there is no steam, less venting is permittable. The finish with Petrobond is finer as well, cutting down on finish work to the part after casting. The sand is a smaller grain because it doesen't need to be as permiable as regular water based green sand.

Chill Plates

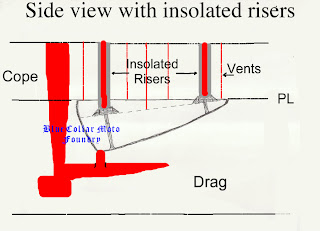

So, first I was gonna use big ol risers. Then I was gonna use chill plates. Then I kept on reading and I learned about insulated risers. The big deal about the large risers was how much extra metal I would have to melt. They would have to be larger than the area they are feeding. In the case of my gas tanks that would be about a 1 1/2 riser. I don't know for sure yet but I'm thinking the insulated risers could be the same size or smaller than the tank mounting points they would be feeding? They would use extra metal, but if small enough that would be acceptable. One advantage to using a riser over a chill plate I cant get out of my head, is that they would not only help supply liquid metal to the mounting points, but the whole area around where they are located. Then again, I could just be imagining the whole thing. Either way, I want to try both ideas. If they both work great then I'll make my decision based on which one was faster, easier to make, and the amount of metal used to pour the mold.

Insolated Risers

A third option would be to use large metal washers as the chill plates, and puting a small riser up threw the center hole. The risers would only help fill the shrinking metal for a short period of time though, and I don't know if it would be worth the effort. It would however be an excellent place to mount a vent...

PS. Nothing about these drawings is to scale. Just my doodles to get a better idea of what I'm doing.

PS. Nothing about these drawings is to scale. Just my doodles to get a better idea of what I'm doing.

Side View of lower tank half.

I did these drawings just to give me a better idea of what was getting messed up in my head. They are from the point of view of the PL (Parting Line) of the way the tank will sit in the cope and drag, not on a bike. I was just trying to figure what the half of the core would look like, but until I drew them I didnt realize that the rear mounting point would extend above the drag into the cope. This realization changed what I thought would be a simple pattern into a more complex one. I'll explain in detail about why this is more complex when I actually make the pattern and post pix of how to set them in sand. Always better to figure things out on paper b4 cutting into expensive materials trying to make a pattern.

Intro

Since I stopped posting on the New Blue Collar Moto blog I've had a bunch of time to work on other projects. Studying about how to cast metal parts has filled a large part of my free time. I cant seem to get enough of it! I've been wanting to start doing foundry work for years now. Ever since that fucker in the BMW hit me on my bike on the 405 and broke my ankle. This was long before I even had a computer. I sat there and drew motorcycle parts I wanted to make some day.

The problem for me began when I couldn't even get a foundry to return my call about doing the work. Most places have less than no interest in doing small production runs at an affordable price for a blue collar guy. I'm sure the number of people with good ideas who have given up simply becouse they had no place to get there work done would stager the mind! I figured that if I'm gonna get something worth doing done, I had better learn how to do it myself. That's the American way isnt it? It was once apon a time anyway. So I set out (without a computer) to learn all I could about metal casting. Anybody here remember what a library is? I found some books for sale and started my small personal library of foundry practices.

Its been about seven years now since I started my mission to find info on how to do it myself. The computer has given me a real helping hand in finding out what I need to know. One of the best on line resources for anyone who wants to start a small foundry is Backyard Metalcasting.com. I first signed up there in April of 2008. There is sooooo much stuff there to read! I'll be posting links and talking about books, supply houses, etc, in future posts. Nuf said for now that there is plenty of info out there if someone wants to learn how to do it for themselves.

Its my plan to take in outside work once I get things going in addition to making my own stuff. I already have an order for 100 hot rod intake manifolds from a friend of mine. The amount of aluminum needed to make the manifolds will determine how large my blast furnace will be. I may have to step up from a No.6 (about 5lb of aluminum) to a No.8 Crucible to accommodate the amount of metal needed for the pour. This will be as large as I go.

Just today I went for a ride in the rain to check out a 1200sq' place in Fullerton where I can get things going. I'm stoked! I'll have to get back to work with the union for a few months to save up the cash for first and last along with supplies, and some remodeling so I can live there in the shop. Shower, kitchen cabinets, gas stoves, counter tops, lumber, refrigerator, futon, etc. Donations are welcome. If you know of anyone trying to get rid of this stuff drop me a mail at bluecollarmoto@aol.com. I wont have anyplace to put any of it till I move in to the shop but keep a eye out for me.

The problem for me began when I couldn't even get a foundry to return my call about doing the work. Most places have less than no interest in doing small production runs at an affordable price for a blue collar guy. I'm sure the number of people with good ideas who have given up simply becouse they had no place to get there work done would stager the mind! I figured that if I'm gonna get something worth doing done, I had better learn how to do it myself. That's the American way isnt it? It was once apon a time anyway. So I set out (without a computer) to learn all I could about metal casting. Anybody here remember what a library is? I found some books for sale and started my small personal library of foundry practices.

Its been about seven years now since I started my mission to find info on how to do it myself. The computer has given me a real helping hand in finding out what I need to know. One of the best on line resources for anyone who wants to start a small foundry is Backyard Metalcasting.com. I first signed up there in April of 2008. There is sooooo much stuff there to read! I'll be posting links and talking about books, supply houses, etc, in future posts. Nuf said for now that there is plenty of info out there if someone wants to learn how to do it for themselves.

Its my plan to take in outside work once I get things going in addition to making my own stuff. I already have an order for 100 hot rod intake manifolds from a friend of mine. The amount of aluminum needed to make the manifolds will determine how large my blast furnace will be. I may have to step up from a No.6 (about 5lb of aluminum) to a No.8 Crucible to accommodate the amount of metal needed for the pour. This will be as large as I go.

Just today I went for a ride in the rain to check out a 1200sq' place in Fullerton where I can get things going. I'm stoked! I'll have to get back to work with the union for a few months to save up the cash for first and last along with supplies, and some remodeling so I can live there in the shop. Shower, kitchen cabinets, gas stoves, counter tops, lumber, refrigerator, futon, etc. Donations are welcome. If you know of anyone trying to get rid of this stuff drop me a mail at bluecollarmoto@aol.com. I wont have anyplace to put any of it till I move in to the shop but keep a eye out for me.

Subscribe to:

Posts (Atom)